-

01

Automated production line

Improve production efficiency, reduce manual errors, and ensure product consistency.

-

02

High precision imported equipment

Adopting advanced production technology from Germany and Japan to improve manufacturing accuracy.

-

03

Flexible production capability

Supports OEM/ODM orders and can customize production according to customer needs.

-

04

Strict quality control system

Each product must undergo at least 5 testing processes to ensure stable quality.

-

05

Fast delivery capability

Efficient production processes ensure the timely delivery of large quantities of orders.

- Home

-

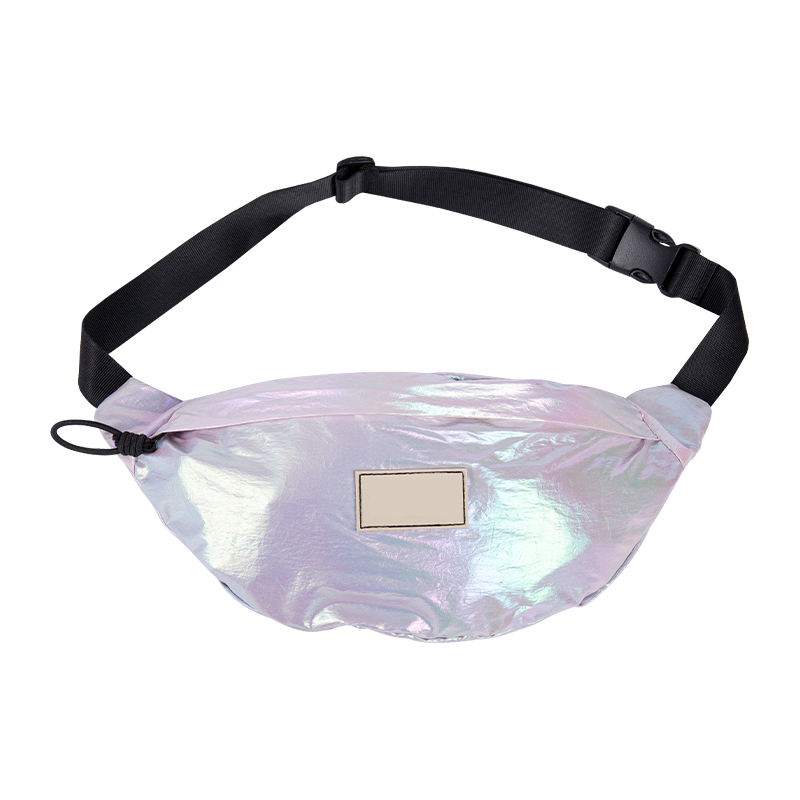

Bags & Backpacks

Travelling BagsPouches & Clutches

- Luggage & Suitcases

-

Accessories

AccessoriesTravel AccessoriesCamera Bags

-

About Us

Why Choose Us?Established in 1999, Huacheng has been deeply involved in the luggage industry for over 30 years, not only manufacturing luggage, but also shaping the way of travel. We focus on designing, producing, and selling high-quality bags and suitcases, integrating innovative craftsmanship with human centered design to ensure that each product combines functionality and aesthetic value.

Coming From China, Marketing To The World.

Coming From China, Marketing To The World. - Contact Us

English

English Español

Español عربى

عربى