Travel backpacks are made from a range of materials, each chosen to balance durability, weight, weather resistance, and cost. The most commonly used materials include synthetic fabrics like nylon and polyester, with some higher-end options incorporating advanced weaves, coatings, or blends. Here's a detailed look at the most common materials and how they affect performance:

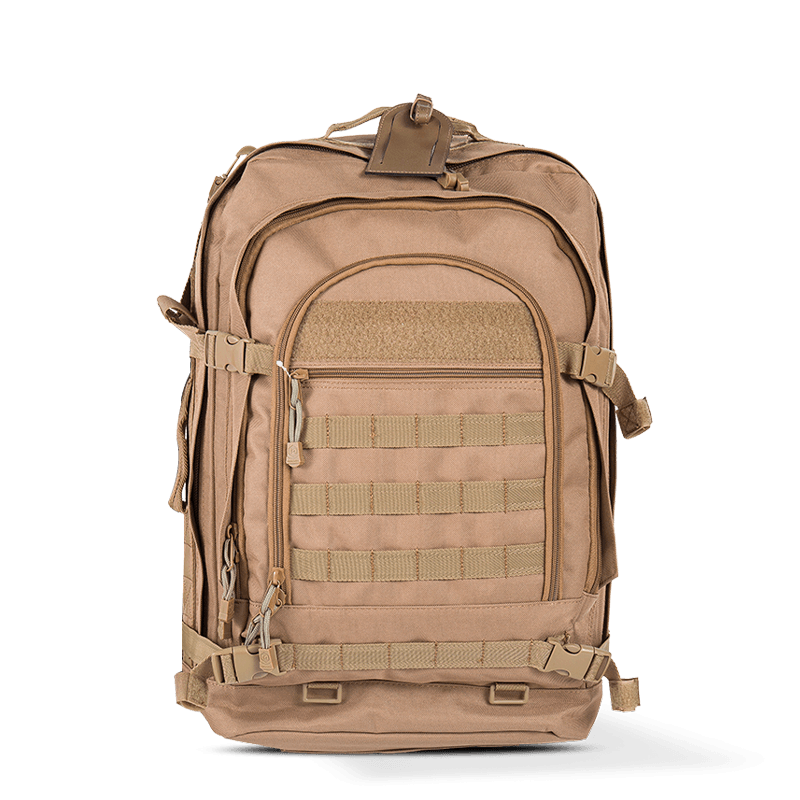

Nylon (especially ripstop and ballistic nylon)

Nylon is one of the most widely used materials for travel backpacks due to its high strength-to-weight ratio. Ripstop nylon is reinforced with a crosshatch pattern that resists tearing and abrasion, making it ideal for rugged travel. Ballistic nylon is even thicker and more durable, originally developed for military use.

Impact: Nylon is extremely durable and resistant to wear and tear. It also holds up well in a variety of climates. However, unless treated with a waterproof coating, it is not inherently waterproof.

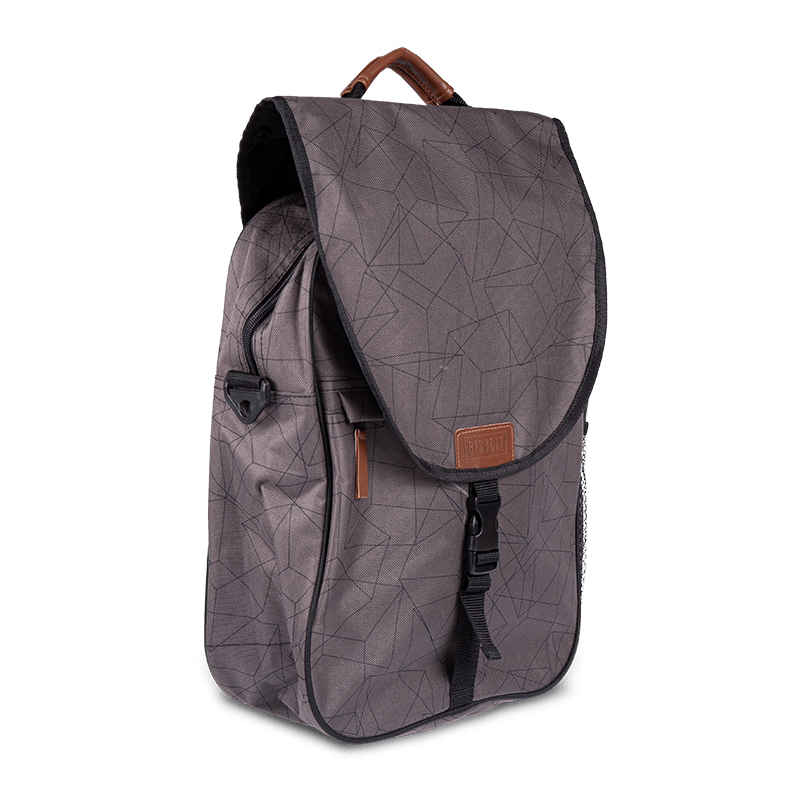

Polyester

Polyester is another common fabric found in travel backpacks. It is generally less expensive than nylon and offers decent strength and color retention. While slightly less durable than nylon, it still provides good resistance to abrasion and UV exposure.

Impact: Polyester backpacks are usually more affordable and can perform well in casual travel settings. With the right treatment or lining, they can also be water-resistant, though typically not as durable as nylon in extreme conditions.

Cordura® Fabric

Cordura is a brand name for a family of nylon-based fabrics known for exceptional durability and resistance to abrasion and scuffs. It comes in different weights and weaves, often used in high-end backpacks for demanding travel.

Impact: Cordura provides superior strength while maintaining a manageable weight. It is excellent for long-term travel and outdoor use, especially when combined with weatherproof coatings.

Canvas (Waxed or Synthetic Blends)

Traditional cotton canvas is sometimes used in vintage-style travel backpacks. Modern canvas blends often incorporate synthetic fibers and are treated with wax or polyurethane for water resistance.

Impact: Waxed canvas has a classic appearance and is fairly durable, but it is generally heavier than synthetic options. While water-resistant, it is less suitable for prolonged exposure to moisture unless specially treated.

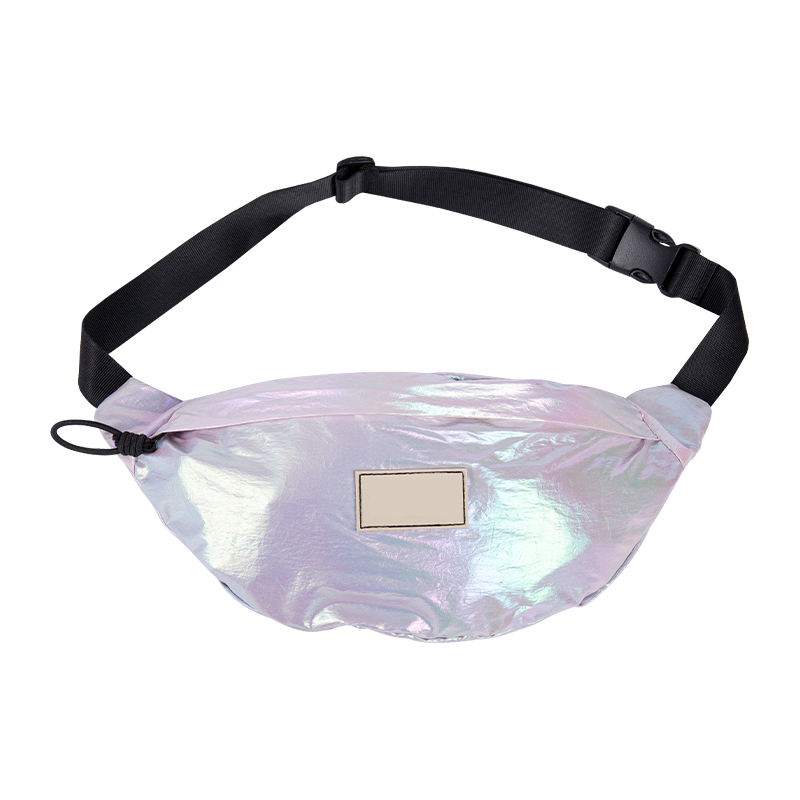

TPU (Thermoplastic Polyurethane) and PVC Coatings

Many backpacks include fabrics coated with TPU or PVC for enhanced waterproofing. These coatings can be applied to nylon or polyester to prevent water from penetrating the surface.

Impact: These coatings greatly improve water resistance, making the backpack suitable for wet environments or travel in rainy regions. However, they may reduce breathability and can add weight or stiffness.

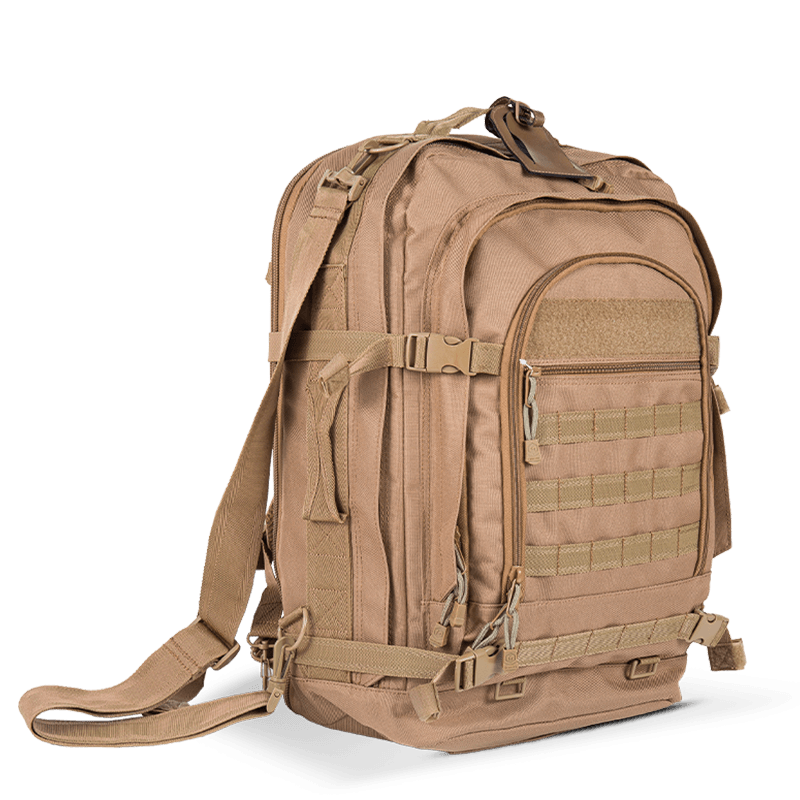

Mesh and Foam (for Back Panels and Straps)

While not part of the main body, breathable mesh and foam padding are often used in back panels, shoulder straps, and hip belts to provide comfort and ventilation.

Impact: These materials improve ergonomic support and help keep the user cool during extended wear. However, they can absorb water and take time to dry if not quick-drying or treated.

Zippers and Hardware (YKK, SBS, Duraflex)

While not a fabric, the quality of zippers and hardware (like buckles and clips) significantly affects durability and weather performance. Brands like YKK are known for high-quality zippers that resist corrosion and damage.

Impact: Durable hardware ensures the backpack holds up under stress and exposure to environmental elements like dust and moisture.

The choice of material in a travel backpack affects not just its longevity and resistance to rough use, but also how it performs in different weather conditions. For most travelers, a high-denier nylon or polyester fabric with a water-resistant coating provides an ideal balance of weight, durability, and protection. Higher-end models may use Cordura or incorporate TPU laminates for even better performance in extreme environments.

English

English Español

Español عربى

عربى